Calcite Formation, Crystals, and Uses

Xingaonai

Xingaonai

![[list:date style=M.d,Y]](/images/date.png) Mar.13,2025

Mar.13,2025

17

17

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Calcite formation environment

Calcite is mainly composed of marble and limestone and is a common calcium carbonate mineral. As a common mineral, calcite mainly appears in sedimentary rocks, especially limestone. It is formed at a specific temperature through biochemical deposition and other processes. When in a low-temperature environment such as an ocean or lake containing calcium bicarbonate, calcium bicarbonate will decompose into calcium carbonate, thereby precipitating to form calcite. In addition, calcite may also be formed in some high-temperature environments, such as areas of volcanic activity. Calcite formed in these high-temperature environments generally coexists with other minerals and may be affected by hydrothermal activity and metamorphism.

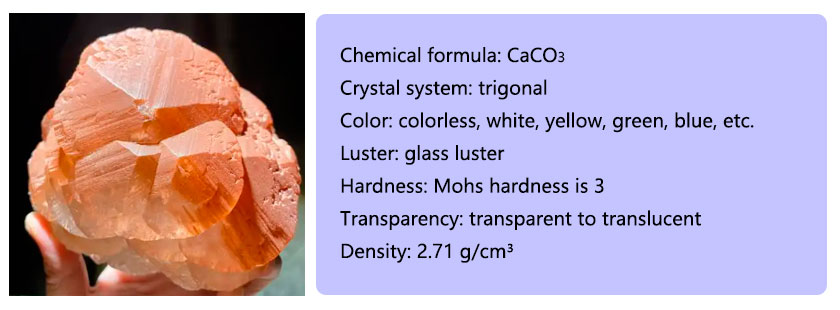

Calcite crystal structure

Calcite belongs to the trigonal system and has a variety of crystal forms. It generally appears in white or colorless form, mostly in the shape of cubes, polyhedrons, hexagonal columns, etc. The crystal structure of calcite has obvious characteristics and is composed of calcium ions and carbonate ions arranged according to a certain rule. In addition, when light passes through calcite, it will decompose into two refracted rays. The double refraction phenomenon is closely related to optical properties and plays an important role in gem identification and optical instruments.

Properties of Calcite

Calcite is not easily soluble in water at room temperature, but is easily soluble in acidic solutions and has good chemical stability. It acts as a neutralizer when neutralizing acidic substances.

Calcite has a transparent to translucent glass luster, mostly white or colorless, with a density and hardness of 2.7 and 3 respectively. In addition, calcite has good thermal stability and is a good heat-resistant material.

Uses of Calcite

Construction industry: Calcite is one of the important raw materials for building materials. It is often used to make gypsum boards, lightweight partition boards, etc., which make them soundproof, heat-insulating, flame-retardant and other properties.

Plastic industry: Plastic products mixed with calcite have good toughness and strength, and at the same time improve the flame retardancy and durability of plastic products.

Papermaking industry: After adding calcite filler to the pulp, the smoothness and glossiness of the paper can be improved, while also reducing the water absorption of the paper and enhancing the hardness and strength of the paper.

Chemical industry: Calcite is used to make gypsum powder, gypsum front panels and other chemicals to make floors, walls, etc., which have the functions of sound insulation, moisture resistance and heat preservation.

Pharmaceutical industry: Calcite can be used to make medicinal gypsum, which can treat trauma and fractures. In addition, calcite can be used as a calcium supplement to supplement calcium, effectively preventing and treating osteoporosis.

Metallurgical industry: The sulfur element contained in calcite can be used as an ironmaking agent to react with the impurity sulfur in the metal, effectively removing impurities in the metal and improving the quality of the metal.

Environmental protection industry: Calcite can be used as a flue gas desulfurizer to react chemically with sulfides in industrial waste gas to generate non-volatile calcium sulfate, effectively reducing the pollution of sulfides to the atmosphere.

Calcite sand making equipment recommendation

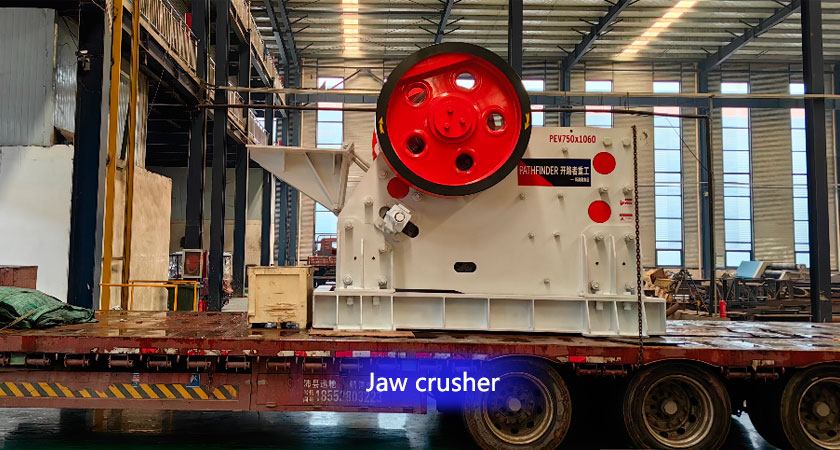

Jaw crusher has the advantages of strong adaptability, simple structure, stable operation, efficient crushing, simple operation, convenient maintenance, energy saving and environmental protection. The working principle of the jaw crusher is to use the gap between the two jaw plates to squeeze and bend large pieces of coal to break them into small pieces. It is the preferred crushing equipment for coarse crushing operations.

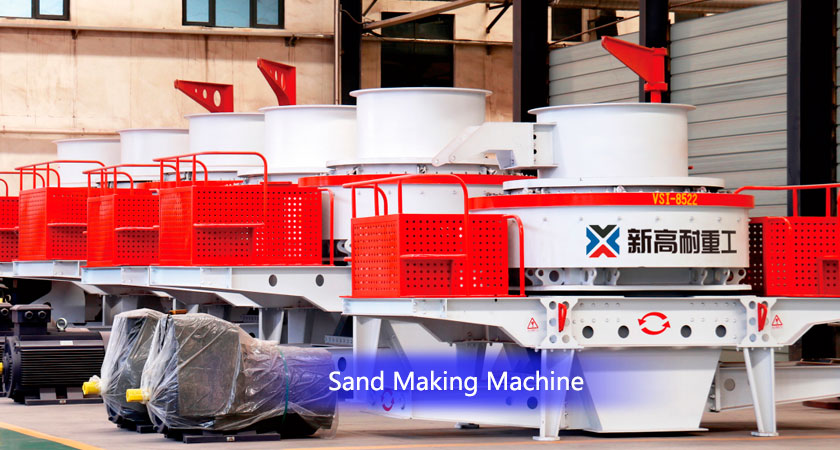

VSI sand making machine has the advantages of compact structure, efficient sand making, good stability, adjustable particle size, high degree of automation, and low operating cost. It uses the principle of high-speed rotating materials breaking each other by themselves and the friction between materials, and is the preferred equipment in sand making operations.

Author: Xingaonai

Reprint address: http://xingaonai.cn/products-knowledge/calcite-formation-crystals-uses.html

+86 17761642222

+86 17761642222 sales@xgnchina.com

sales@xgnchina.com

Message

Message Chat Now

Chat Now