How to solve the problem of ball mill selection

Xingaonai

Xingaonai

![[list:date style=M.d,Y]](/images/date.png) May.15,2025

May.15,2025

3

3

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

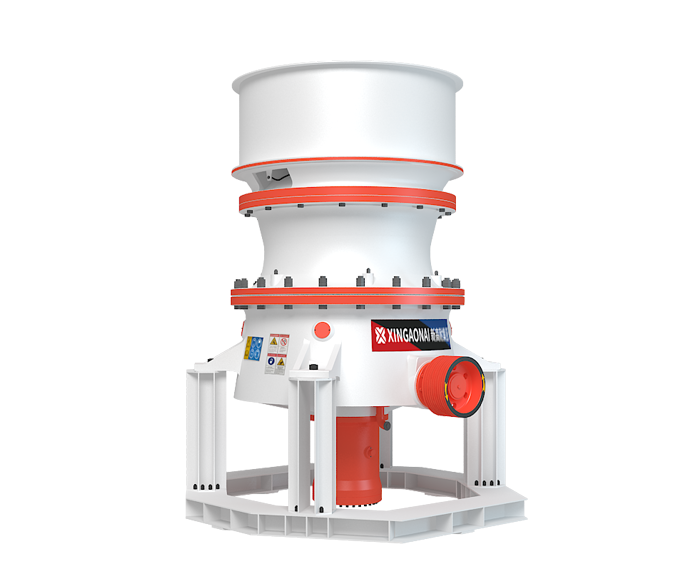

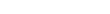

Ball mill is an important grinding equipment on industrial production lines. In order to meet different production needs, there are many types of ball mills. When purchasing a ball mill, users must choose a suitable type of ball mill equipment in combination with actual production needs. This article analyzes the selection of ball mills for user reference.

1. Understand the mineral properties of the material to be ground. There are many types of materials in nature. The hardness, viscosity and humidity of each ore material are different. When the ball mill grinds the relevant materials, the production efficiency, production capacity, etc. are different. When users purchase a ball mill, they need to choose it in combination with the materials to be ground.

2. Clarify the specific production requirements. Different users have different production requirements. Some users have high requirements for fineness, and some users require the fineness of the material to be within a certain range. At this time, the ball mill model selected by the user is different. In addition, on some production lines, it may be necessary to choose a professional ball mill. For example, on a mineral processing production line, a mineral processing ball mill can better guarantee the quality of mineral processing than an ordinary ball mill.

3. According to the amount of output, choose the diameter and length of the ball mill that suits the production needs. Different users have different unit production capacity requirements for ball mills, so the diameter and length of the ball mills to be selected are also different. Because the diameter and length of the ball mill are different, the bearing capacity of the ball mill is also different, so users need to select the model according to the actual production capacity requirements.

4. Choose an energy-saving and consumption-reducing ball mill. The ball mill is large in size, heavy in tonnage, and slow to start, so the energy consumption is large. However, with the continuous updating of ball mill technology, the energy-saving ball mill developed by ball mill manufacturers has been put on the market. It is recommended that users choose this type of energy-saving ball mill, which can not only reduce the production cost of users, but also the production process is more environmentally friendly, which is in line with the current trend of energy conservation and environmental protection.

5. Choose a ball mill with good quality. There are many ball mill manufacturers on the market, and the equipment quality of each ball mill manufacturer is also different. On the one hand, a good ball mill can ensure the stability of the ball mill during operation. On the other hand, the long-term operation of the ball mill will cause a lot of wear and tear on the parts, especially the liner. The ball mill liner selected by the user is recommended to be made of high wear-resistant material, which can not only reduce the replacement frequency of the liner, but also ensure that the user can continuously and productively invest in production.

The selection of ball mill is very important. The above analysis is made from five perspectives. If you have any questions, you can consult the customer service online for free to learn more details.

Author: Xingaonai

Reprint address: http://xingaonai.cn/products-knowledge/920.html

+86 17761642222

+86 17761642222 sales@xgnchina.com

sales@xgnchina.com

Message

Message Chat Now

Chat Now