Working principle and parameter specification analysis of spiral classifier

Xingaonai

Xingaonai

![[list:date style=M.d,Y]](/images/date.png) May.15,2025

May.15,2025

4

4

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

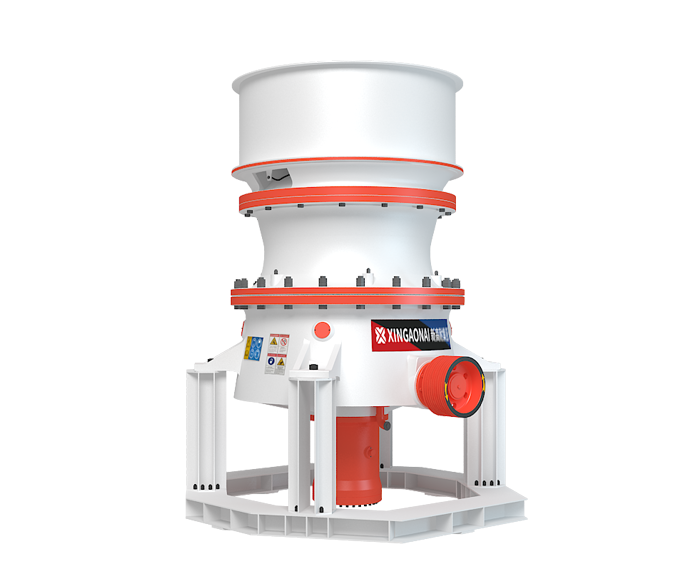

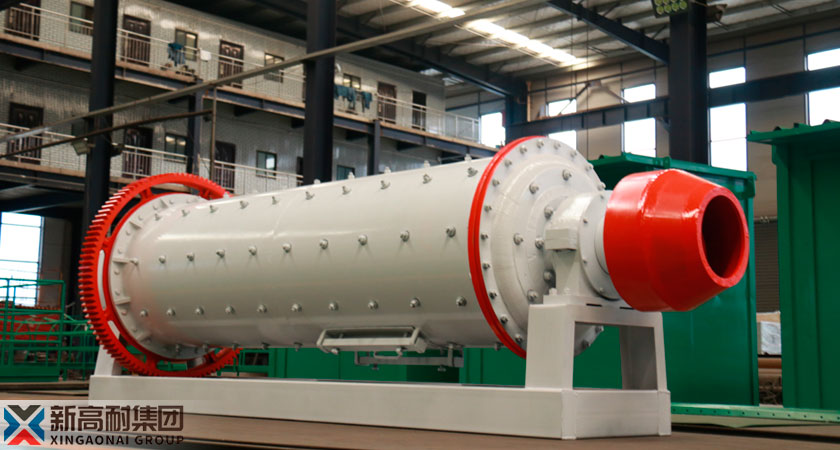

Spiral classifier, one of the types of industrial classifiers, often cooperates with grinding equipment such as ball mills to form a closed circulation loop, and plays a grading role in various mineral beneficiation production lines. This article mainly briefly analyzes the working principle and parameter specifications of the spiral classifier, aiming to help more corporate users who pre-invest in the spiral classifier equipment to make better choices. The specific details are as follows:

1. Working principle of spiral classifier

When the spiral classifier works, it mainly relies on the principle that the solid particles have different sizes and specific gravities, and thus have different sedimentation speeds in the liquid. Fine ore particles float in the water and overflow, and coarse ore particles sink to the bottom of the tank. Then the spiral pushes it to the upper part and discharges it for mechanical grading. A grading equipment that can filter the powder ground in the mill, and then use the spiral vanes to rotate the coarse material into the mill feed port, and discharge the filtered fine material from the overflow pipe, thereby realizing the sorting of minerals.

Spiral classifier operation simulation animation

Single spiral classifier operation simulation animation

II. Spiral classifier parameter specification model table

Here, the spiral classifier produced by Henan xingaonai classifier manufacturer with relatively complete spiral classifier parameter specifications is taken as an example.

III. Detailed explanation of spiral classifier parameters

Liming has focused on the production of mining equipment for more than 30 years. There are about 20 kinds of spiral classifiers produced. Each spiral classifier with different model parameters has certain differences in spiral diameter, spiral speed, water tank length and unit time processing volume. Therefore, users need to make reasonable purchases according to their actual needs. The detailed explanation of the specific spiral classification parameters is as follows:

1. The inclination of the water tank is determined according to the process requirements, generally between 12°-18°30′, and the smaller value is taken when the classification particle size is required to be fine.

2. The overflow weir height of the high weir spiral classifier is 1/4-3/8 of the spiral diameter, and the submerged spiral classifier is 3/4-1 of its diameter.

3. The length of the spiral shaft is determined by the overflow weir height, which is determined by the spiral diameter and the length L of the sand return dehydration zone. The length L of the sand return dehydration zone depends on the sand return water content required by the mill and the size and position of the mill, usually L=1.5-2m.

4. The spiral lead is related to the amount of sand return, the spiral diameter and the speed. Practice has shown that it is generally 0.5-0.6 times the spiral diameter. The speed should be able to ensure timely return of sand settling without causing strong stirring, ensuring that the overflow fineness required by the process is achieved.

The above is a brief analysis of the working principle and parameter specifications of the spiral classifier. For more information about the price of the spiral classifier, selection precautions and other equipment details, you can consult Henan Liming online for free. Here are professional spiral classifier technicians who will answer you in detail online in real time.

Author: Xingaonai

Reprint address: http://xingaonai.cn/products-knowledge/921.html

+86 17761642222

+86 17761642222 sales@xgnchina.com

sales@xgnchina.com

Message

Message Chat Now

Chat Now