VSI Series Vertical Shaft Impact Crusher

Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

- Feeding Size: ≤60mm

- Processing Capacity: 70-640t/h

Applicable materials: VSI series vertical shaft impact crushers are suitable for fine crushing and sand making operations of various hard stone materials such as granite, diabase, basalt, iron ore, etc.

PRODUCT INTRODUCTION

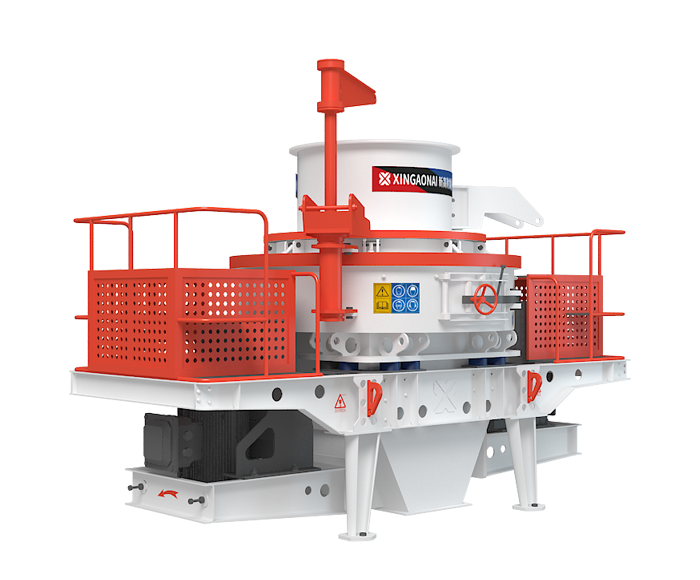

The VSI series vertical shaft shock crusher is widely applicable to the medium and fine -crushing operations of various hard and crisp materials such as rocks, abrasives, refractory materials, cement strokes, iron ore, concrete aggregate and other kinds of fine materials, its special rotor structure design, optimized crushing speed, wear -resistant material technology and hydraulic design can efficiently meet the demand for modern sand and gravel, and provide high -quality sand and gravel aggregate for multiple fields,it is one of the preferred equipment in the field of artificial sand and stone plastic surgery.

- Scope of application: VSI series vertical shaft impact crushers are widely used in the crushing and sand making of materials in mining, construction, abrasives, metallurgy and other fields.

- Internal Structure: The sand making machine is composed of seven parts: feed, distributor, vortex crushing chamber, impeller experience, spindle assembly, base transmission device and motor.

Advantages

- 1、Feeding method flexible aiverse: By adjusting the hopper feeding device, it is easy to achieve the conversion between the two modes of "falling feeding + centre feeding" and "full centre feeding". Adjusting the angle of the distribution plate can avoid the direct impact of the material on the impeller and reduce the abnormal wear of the impeller.

- 2、Large throughput: The design of the large discharge port makes the material unloading more smoothly, which effectively prevents material blockage, avoids abnormal damage to the equipment, and improves the crushing efficiency.

- 3、Hydraulic device maintenance is convenient: Advanced hydraulic opening and hanging devices can easily hang into the hopper, hanging plates, impeller, bearings, etc., effectively reduce the difficulty of daily maintenance and maintenance of the equipment, and save labor time.

- 4、Four -mouth impeller cost reduction and efficiency: The new four-port impeller design, compared with the crushing of the same material with the three-port impeller, the crushing efficiency is increased by about 20%, and the service life of the impeller is extended by 30~150%.

- 5、High quality vulnerable parts are wear-resistant and durable: The transmission part and core component are reasonable, extend the life span of easy loss of the loss, effectively reduce the maintenance time of the shutdown and the wear of the loss of the loss,and the Zhouhu plate can be used up and down after all grounding, the utilization rate is high, and the operating cost is low.

WORKING PRINCIPLE

The principle of impact crushing, the rotor sprays the material horizontally onto the impact plane in the crushing cavity through the centrifugal force at a very high speed, and crushes by using the kinetic energy of the material when it moves at high speed.

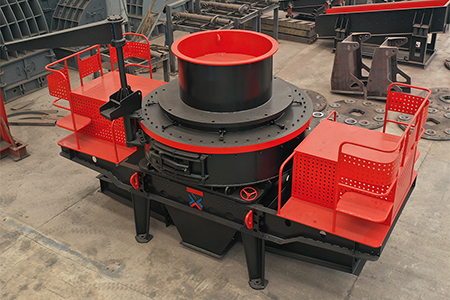

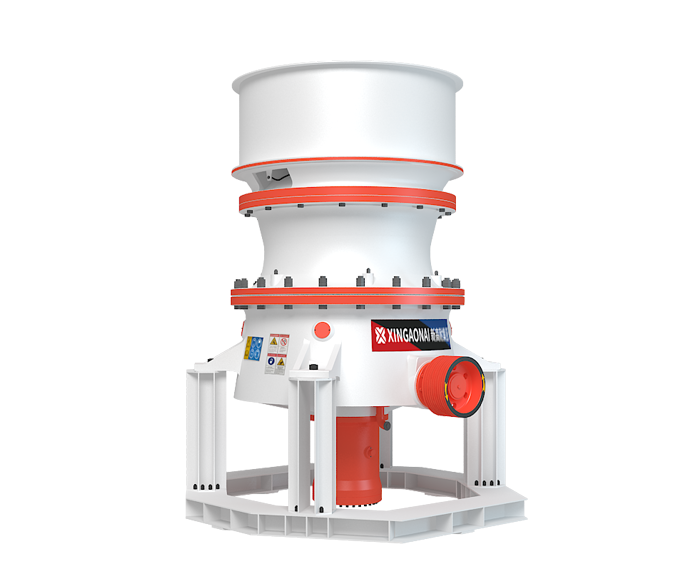

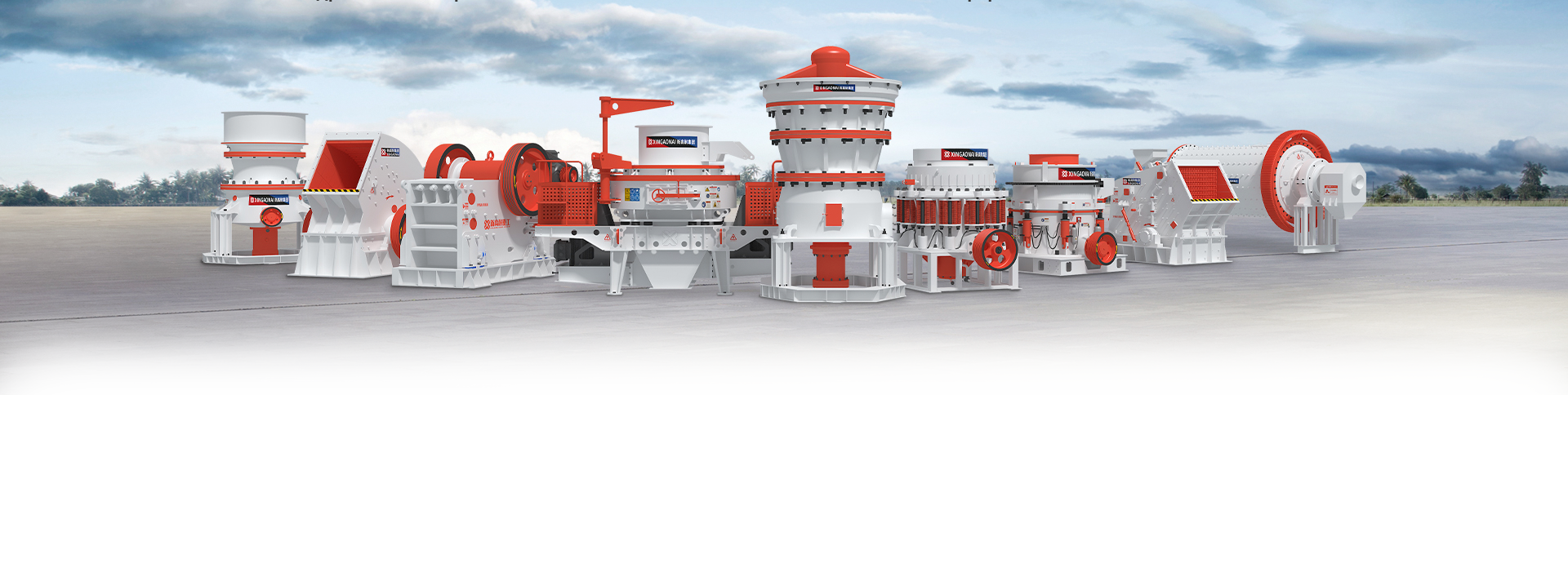

PRODUCT PHOTOS

TECHNICAL SPECIFICATIONS

| Model | Capacity no center feeding (tph) | Capacity center feeding (tph) | The best feed size soft (mm) | The best feed size hard (mm) | Rotating speed (r/min) | Dual motor power (kw) | Dimensions (mm) | Weight (t) |

|---|

| VSI7615 | 150-280 | 70-140 | 35 | 30 | 1700-1900 | 150 | 4100*2320*2300 | 12.1 |

| VSI8522 | 240-380 | 120-200 | 40 | 35 | 1530-1700 | 220 | 4140*2600*2700 | 14.8 |

| VSI9532 | 350-540 | 180-280 | 45 | 40 | 1380-1660 | 320 | 4800*2571*2893 | 18.6 |

| VSI1145 | 500-640 | 250-360 | 50 | 45 | 1200-1390 | 440 | 5450*2850*3335 | 21.5 |

| VSI1150 | 413-442 | 344-368 | 55 | 45 | 1000-1300 | 500 | 5500*2750*3950 | 23 |

| VSI1263 | 545-583 | 454-486 | 60 | 50 | 900-1200 | 630 | 5750*2980*3410 | 24.5 |

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now