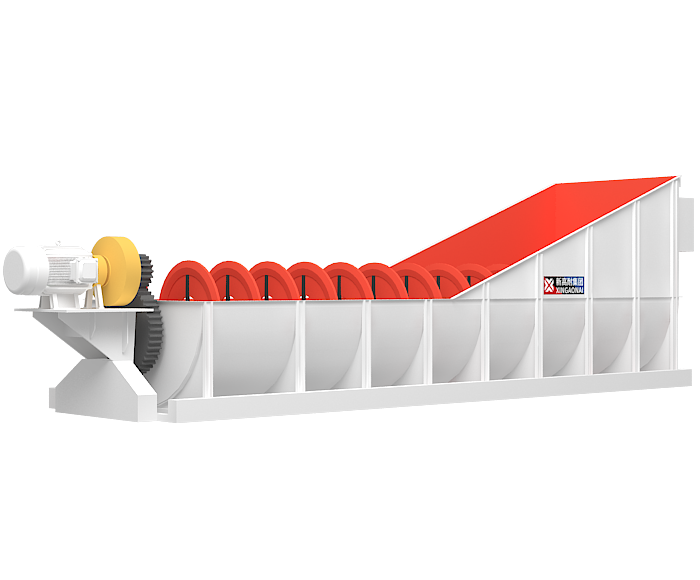

Spiral Sand Washing Machine

Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

- Feeding Size:

- Processing Capacity: 40-300t/h

Applicable materials: The spiral sand washing machine is suitable for washing, grading and impurity removal operations of various materials such as limestone and river pebbles.

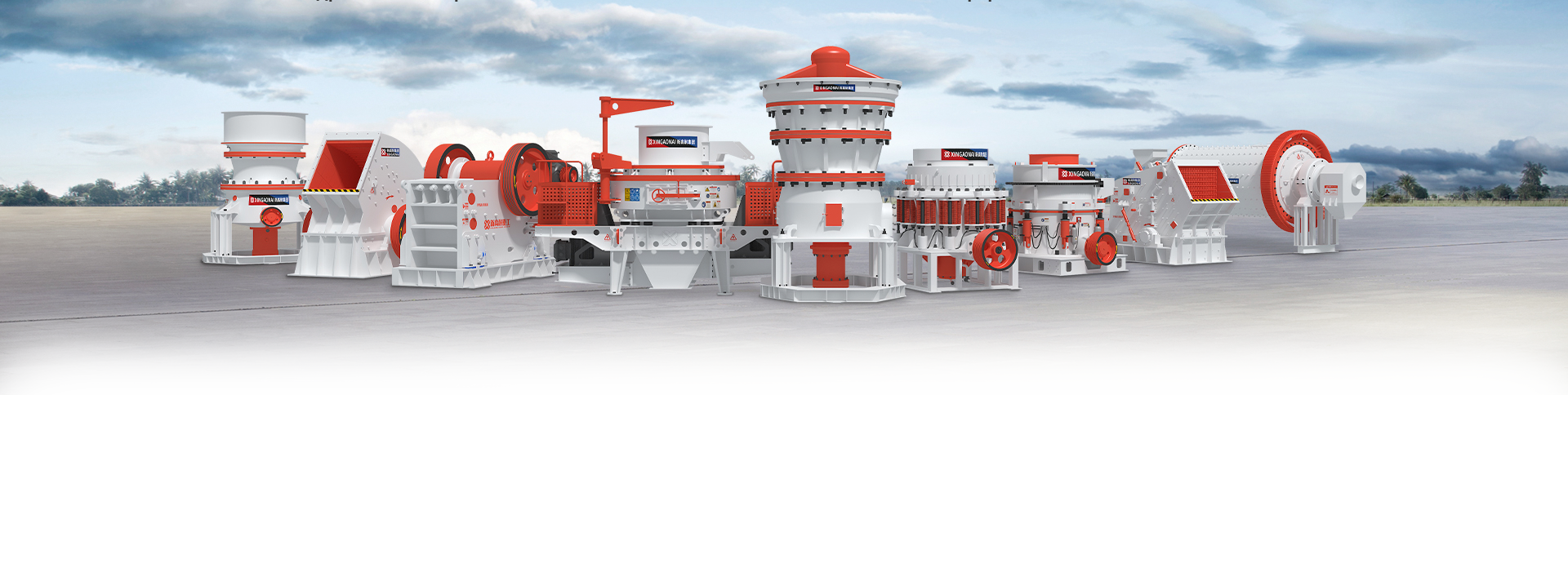

PRODUCT INTRODUCTION

The spiral sand washing machine is a newly designed type of high -efficiency sand and gravel selection equipment in our company,it is often used in conjunction with sand making machines for artificial sand or natural sand washing, grading, and miscellaneous operations, it can effectively clean the soil in the separation of stone powder and meet the needs of modern large sand and gravel production line,it is an ideal choice for the current upgrade of the sand washing industry.

- Scope of application: Spiral sand washing machines are often used in conjunction with ball mills and are widely used in wet sand making processes in mining, building materials, water conservancy and hydropower industries.

- Internal Structure: It is mainly composed of grooves, reducer, motor, central axis, spiral blades and brackets.

Advantages

- 1、Washing effect is good: The external sealing structure, a fully closed oil bath transmission device, plus the clever design of the spiral blades, the sand material has more time and number of times, the water content of the sand content, the low mud content, and the fine -grained products remain stable,meet the requirements of high -level materials.

- 2、High sand washing efficiency: This device uses a long and scientific use of the spiral device mixing and slurry,the degree of mechanization is high, which can effectively improve the efficiency of sand washing production in the unit time, for rotor sand washing machines, its processing capacity has been greatly improved, and the material of small particle size can also be washed.

- 3、High amount of sorting accuracy: Professional design guide plates and adjustable long overflow weir boards, with optimized spiral speed to ensure the accuracy of material washing and grading; optimize the design drainage groove, effectively ensure that the washed materials are lost less, and the moisture in the material is removed to the maximum extent, and the sewage can be used in circulation.

- 4、Durable and less failure: The unique groove bottom rotor sealing structure, high -wear resistance and strong pressure -resistant raw materials made of spiral blades, plus the high anastomosis between the equipment and accessories, the whole machine runs smoothly, solid and durable, and the whole machine is stable, strong and durable; and the transmission part is separated from water and materials to effectively avoid damage caused by the machine due to water or pollution rust.

WORKING PRINCIPLE

The spiral sand washing machine is usually tilted at 15 °, and the slurry is given from the top of the sandwashing groove, and a certain amount of water is injected into the main groove, the transmission department drives the spiral axis to rotate at a certain speed, forcing the material to flip and roll in the groove body and move towards the discharge port, the fine -grained materials and impurities are taken to the surface of the water surface through the overflow weir, and the thick particles sink to the bottom of the groove and are finally pushed to the outlet, so as to achieve the selection, classification, miscellaneousness and dehydration of the material.

PRODUCT PHOTOS

TECHNICAL SPECIFICATIONS

Model

| Power (mm) | Capacity (mm) | NOTES |

|---|

XL920-8M

| 11 | 40-60 | ZQ400 Reducer |

| 2XL920-8M | 11*2 | 90-120 | ZQ400 Reducer |

| XL1120-8M | 18.5 | 60-80 | ZQ400 Reducer |

| 2XL1120-8M | 18.5*2 | 180-260 | ZQ400 Reducer |

| XL1500-8M | 18.5 | 100-120 | ZQ500 Reducer |

| XL1500-9M | 22 | 100-120 | ZQ500 Reducer |

| 2XL1500-8M | 22*2 | 240-300 | ZQ500 Reducer |

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now