Potash feldspar grinding 300 purpose and required equipment

Xingaonai

Xingaonai

![[list:date style=M.d,Y]](/images/date.png) Mar.25,2025

Mar.25,2025

341

341

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Potassium feldspar is an important silicate mineral in the monoclinic system, also known as orthoclase, which belongs to feldspar minerals. Feldspar is an aluminum silicate mineral of alkali metals or alkaline earth metals such as potassium, sodium, and calcium. It is widely distributed and has abundant reserves. It is mainly distributed in metamorphic rocks, igneous rocks, and sedimentary rocks. After being ground to 300 mesh, potassium feldspar has a wide range of uses and the return on investment is increasing. However, what equipment is needed for the potassium feldspar grinding production line? How much does it cost to produce potassium feldspar grinding per ton? Let's learn more about it here.

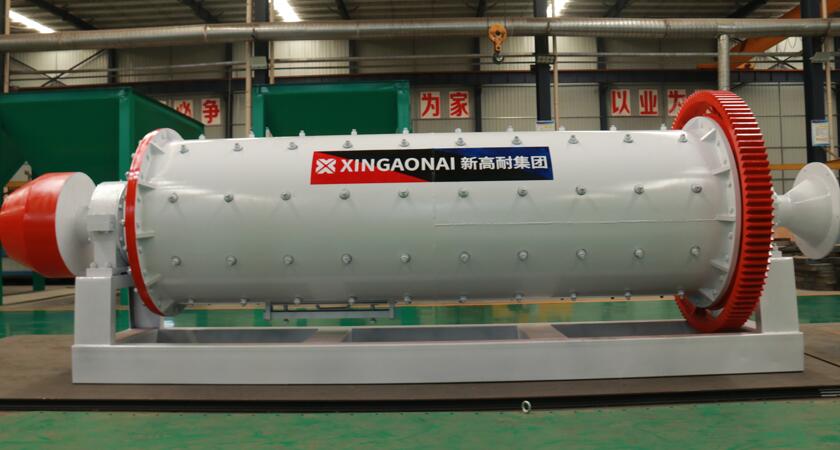

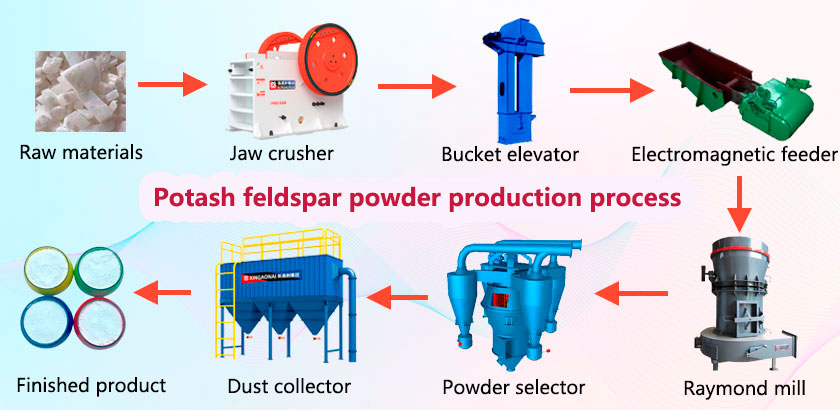

1. Potassium feldspar grinding equipment and production process flow

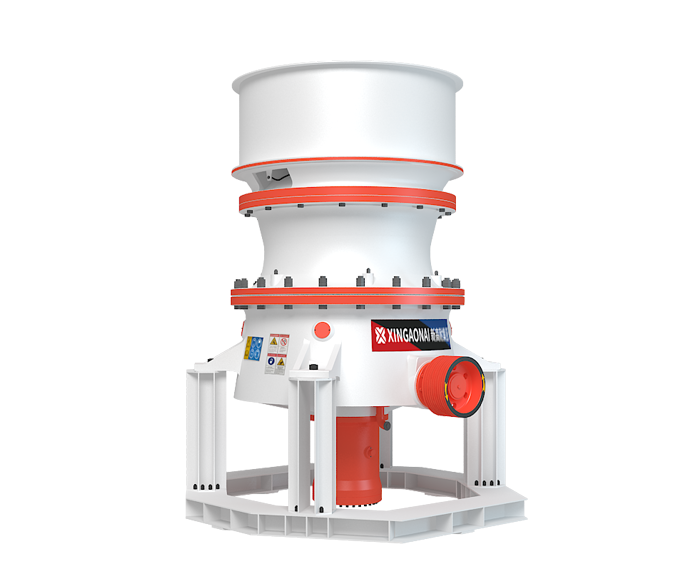

Potassium feldspar is generally white, flesh-colored, gray, yellow, etc., with a density of 2.56g/cubic centimeter, and the hardness has reached level 6. Combined with the material characteristics and the 300-mesh finished product requirements, it is recommended to choose a Raymond mill. In addition, what equipment is needed for the potassium feldspar grinding production line? It is also necessary to combine the particle size, output, and consider the site conditions, floor area, investment budget and other aspects. Here is a tailor-made solution for each customer.

Potassium feldspar grinding equipment

As the main equipment, the Raymond mill is designed through updating and improvement. It has a three-dimensional structure, small footprint, strong completeness, and an independent production system from block materials to finished powder. The workshop can basically realize unmanned operation and high efficiency. With the new pulse dust removal equipment, the dust removal is thorough and pollution is reduced. The finished fine powder is of good quality, uniform, high sorting accuracy, and higher screening rate. The fineness can be adjusted according to demand.

Potassium feldspar powder production process

Raw material warehouse → bucket elevator → jaw crusher → Raymond mill → electromagnetic vibrating feeder → analyzer → powder collector → pipeline device → dust collector → power distribution cabinet → finished product warehouse;

Phase 1: The large pieces of potassium feldspar in the raw material warehouse are evenly sent to the jaw crusher by the vibrating feeder for crushing to the particle size required by the mill (15mm-30mm).

Stage 2: The qualified potassium feldspar material is sent to the silo by the bucket elevator, and then sent to the Raymond mill for grinding by the vibrating feeder.

Stage 3: The ground potassium feldspar powder is graded and screened by the powder selector, and the unqualified stone powder is sent to the mill by the conveyor belt and re-ground until it is qualified.

Stage 4: The powder that meets the fineness enters the dust collector through the air flow through the pipeline for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then packaged uniformly by a powder tanker or an automatic packaging machine.

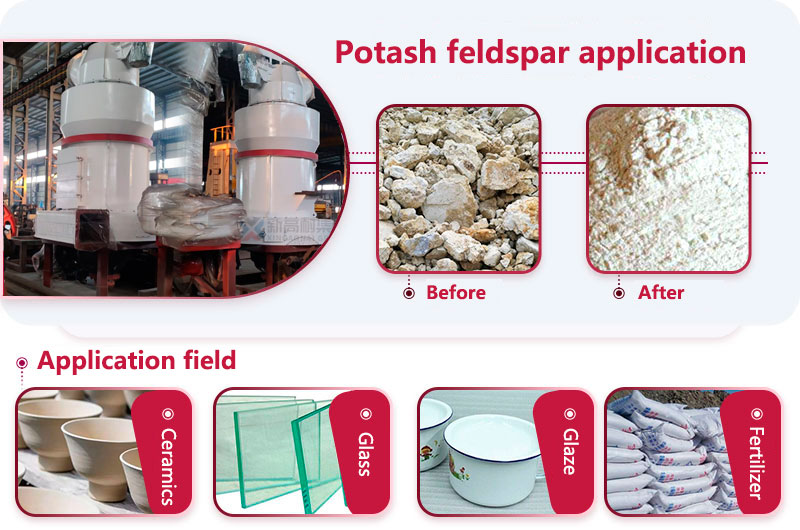

2. Uses of potassium feldspar

Ceramic body ingredients: Potassium feldspar can be used as a flux, which can reduce the firing temperature of ceramics and improve the strength and transparency of the product. It is often used in the production of tiles, tableware, sanitary ware, etc.

Glass industry: Potassium feldspar powder can provide aluminum oxide and potassium oxide, which can effectively improve the chemical stability and mechanical strength of glass. It is often used in the manufacture of flat glass, container glass, optical glass, etc.

Building materials: Potassium feldspar powder can be used as a filler or additive to improve the durability and compressive strength of materials. It is often used to produce building bricks, cement and concrete.

Agriculture: Potassium feldspar powder can be used as a potassium fertilizer, mainly used to supplement potassium in the soil. It can promote plant growth and increase crop yield and quality.

Other industries: Potassium feldspar powder can also be used as a filler or functional additive to improve product performance. It is often used to manufacture industrial products such as plastics, coatings, and rubber.

3. Potassium feldspar grinding production cost

The production process of potassium feldspar is simple and its application field is wide. Many miners call it a highly profitable industry. According to industry insiders, opening a potassium feldspar processing plant can easily make millions of dollars a year. As for the production cost of potassium feldspar grinding per ton, according to the understanding of customers who have already put it into production, it is usually around US$6 (excluding long-term investment). The main costs involved are raw material costs, site, later labor costs, and water and electricity costs, etc. The actual choices are different, and the overall cost is also different.

1. Raw material procurement cost. The price of ore in each region is slightly different, usually 1-2 US dollars/ton.

2. Electricity consumption, depending on the power of the equipment motor, the market price is 0.2-0.3 US dollars/kWh.

3. Water cost, the market price is about 0.4 US dollars/ton.

4. Basic salary of workers, about 30 US dollars/day.

In addition to the above operating costs, there are long-term costs, including infrastructure construction, standardized factory buildings, closed storage warehouses, comprehensive environmental protection facilities, and water supply and drainage, power supply and distribution, and office and living facilities, plus the cost of potassium feldspar powder production line, which is also an expense.

Due to the different actual conditions of each processing plant, the above analysis is for reference only. How much does it cost to produce potassium feldspar grinding powder per ton? For more detailed data, there are professionals to calculate, welcome to consult and understand, and free design and provide technical solutions. New Gaonai Heavy Industry has technology and a field factory, independently develops and manufactures equipment, directly to customers, so the overall more favorable, can directly come to the factory to inspect the equipment, immediately arrange for you!

Author: Xingaonai

Reprint address: http://xingaonai.cn/products-knowledge/potash-feldspar-grinding-300-purpose-and-required-equipment.html

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now