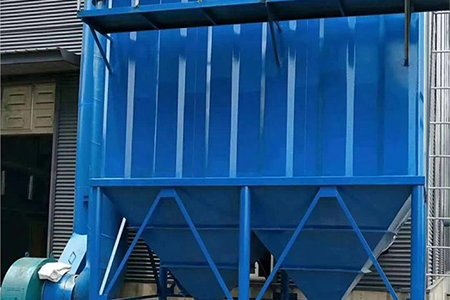

LDMC Series Pulse Bag Filter

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

PRODUCT INTRODUCTION

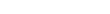

The new pulse bag filter improved by XinGaoNai Group retains the advantages of high purification efficiency, large gas processing capacity, and long filter bag life,solved the problem of open air placement and low pressure of compressed air source, today, it is widely used in the purification of dusty gas and the recovery of materials in mining, metallurgy, building materials and other industries.

Advantages

WORKING PRINCIPLE

Under the traction of fan power, the internal, dust removal pipes and dust cover in the dust collector form a negative pressure environment, make the dust -containing gas enter the dust collector under pressure difference, the airflow is filtered by the dust removal filter bag, and the dust is left on the surface of the bag, input pulse signals regularly through the PLC controller to enter the pulse valve, the high -pressure air of the compressed gas will be blew on the dust on the surface of the filter bag and collect it in the ash accumulation to achieve the purpose of recycling the dust, the clean gas after treatment was discharged from the chimney through the dusty fan.

PRODUCT PHOTOS

TECHNICAL SPECIFICATIONS

| Model | Handling air volume (m³/h) | Entrance concentration (g/Nm³) | Emission concentration (mg/Nm³) | Pressure loss (Pa) | Shell pressure (Pa) | Number of rooms | Number of filter bags | Filter area (㎡) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| LDMC64-8 | 36800 | <1200 | ≤10 | 1470-1770 | -5000 | 8 | 512 | 512 | 14980 |

| LDMC96-4 | 27600 | <1200 | ≤10 | 1470-1770 | -5000 | 4 | 384 | 384 | 9622 |

| LDMC96-5 | 34500 | <1200 | ≤10 | 1470-1770 | -5000 | 5 | 480 | 480 | 12833 |

| LDMC96-6 | 41400 | <1200 | ≤10 | 1470-1770 | -5000 | 6 | 576 | 576 | 14223 |

| LDMC96-7 | 48300 | <1200 | ≤10 | 1470-1770 | -5000 | 7 | 672 | 672 | 15042 |

| LDMC96-8 | 55200 | <1200 | ≤10 | 1470-1770 | -5000 | 8 | 768 | 768 | 16524 |

| LDMC96-9 | 62100 | <1200 | ≤10 | 1470-1770 | -5000 | 9 | 864 | 864 | 17905 |

| LDMC96-2*5 | 69000 | <1200 | ≤10 | 1470-1770 | -5000 | 10 | 960 | 960 | 23439 |

| LDMC96-2*6 | 82800 | <1200 | ≤10 | 1470-1770 | -5000 | 12 | 1152 | 960 | 25200 |

| LDMC96-2*7 | 96600 | <1200 | ≤10 | 1470-1770 | -5000 | 14 | 1344 | 960 | 29400 |

| LDMC96-2*8 | 110400 | <1200 | ≤10 | 1470-1770 | -5000 | 16 | 1536 | 960 | 33600 |

| LDMC96-2*9 | 124200 | <1200 | ≤10 | 1470-1770 | -5000 | 18 | 1728 | 960 | 37800 |

| LDMC96-2*10 | 138000 | <1200 | ≤10 | 1470-1770 | -5000 | 20 | 1920 | 960 | 42000 |

| Model | Handling air volume (m³/h) | Entrance concentration (g/Nm³) | Emission concentration (mg/Nm³) | Pressure loss (Pa) | Shell pressure (Pa) | Number of rooms | Number of filter bags | Filter area (㎡) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| LDMC128-6 | 67300 | <1300 | ≤10 | 1470-1770 | -6800 | 6 | 768 | 936 | 20224 |

| LDMC128-9 | 100900 | <1300 | ≤10 | 1470-1770 | -6800 | 9 | 1152 | 1406 | 26400 |

| LDMC128-10 | 112100 | <1300 | ≤10 | 1470-1770 | -6800 | 10 | 1280 | 1561 | 31732 |

| LDMC128-2*6 | 134560 | <1300 | ≤10 | 1470-1770 | -6800 | 12 | 1536 | 1874 | 36000 |

| LDMC128-2*7 | 157000 | <1300 | ≤10 | 1470-1770 | -6800 | 14 | 1792 | 2186 | 43900 |

| LDMC128-2*8 | 179400 | <1300 | ≤10 | 1470-1770 | -6800 | 16 | 2048 | 2498 | 50000 |

| LDMC128-2*9 | 201900 | <1300 | ≤10 | 1470-1770 | -6800 | 18 | 2304 | 2810 | 55400 |

| LDMC128-2*10 | 224300 | <1300 | ≤10 | 1470-1770 | -6800 | 20 | 2560 | 3123 | 60000 |

| LDMC128-2*11 | 247600 | <1300 | ≤10 | 1470-1770 | -6800 | 22 | 2816 | 3435 | 65400 |

| LDMC128-2*12 | 269100 | <1300 | ≤10 | 1470-1770 | -6800 | 24 | 3072 | 3748 | 72000 |

| LDMC128-2*13 | 291600 | <1300 | ≤10 | 1470-1770 | -6800 | 26 | 3328 | 4060 | 78000 |

| LDMC128-2*14 | 314000 | <1300 | ≤10 | 1470-1770 | -6800 | 28 | 3584 | 4372 | 84000 |

| LDMC128-2*15 | 336400 | <1300 | ≤10 | 1470-1770 | -6800 | 30 | 3840 | 4685 | 90000 |

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now