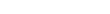

Iron ore crushing process

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Iron ore

Process introduction: Pure magnetite can be directly put into the furnace to make iron, but the associated ore is more, for some impurities relatively high magnetite to carry out simple crushing and screening, grinding magnetic separation to produce concentrate

Application areas: Iron ore is mainly used in steel production and is an important raw material for steel production enterprises.

Process introduction

crushing and screening

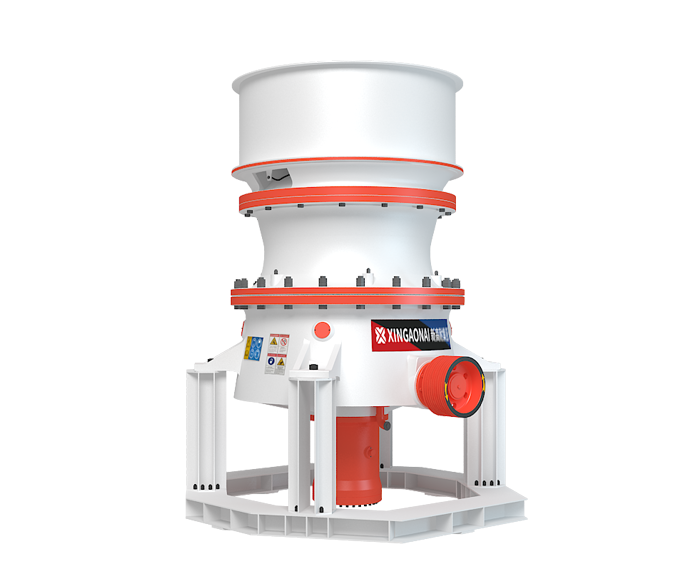

The bulk iron ore is uniformly sent to the jaw crusher or the coarse crushing moving station through the silo by the vibrating feeder. After the coarse crushed iron ore is sifted by vibrating screen, it is sent by belt conveyor to the single cylinder hydraulic cone crusher for crushing; The iron ore material after medium crushing is sent to multi-cylinder hydraulic cone crusher for fine crushing.

grinding

The 0-12mm iron powder sifted by the vibrating screen is uniformly sent to the grinding machine for grinding, and screened by the spiral classifier, and those that do not meet the requirements are sent to the grinding machine for continued grinding.

magnetic separation

The iron powder that meets the dressing requirements is sent to the magnetic separator for strong magnetic separation and magnetic separation to remove debris.

drying

The obtained iron powder is sent to the dryer to dry and the iron powder can be obtained.

Production instance

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now