What factors are related to ball mill production capacity and how to improve it

Xingaonai

Xingaonai

![[list:date style=M.d,Y]](/images/date.png) Mar.28,2025

Mar.28,2025

546

546

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

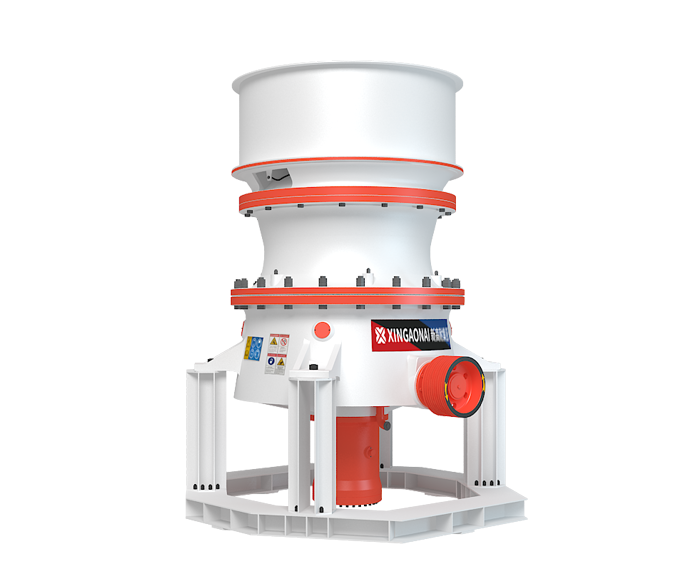

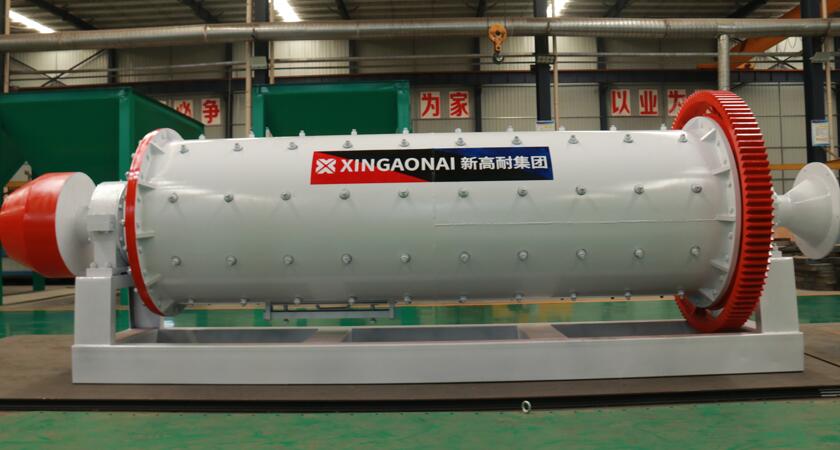

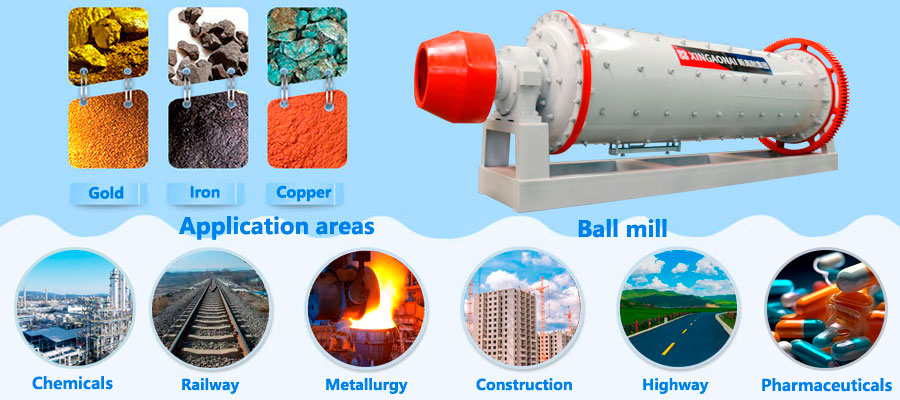

Ball mills are familiar to all those who work in the mining, building materials and other industries. They are mainly used for grinding and processing various ores (gold, iron, molybdenum, copper, etc.), steel slag, coal, etc. They are generally characterized by high efficiency, energy saving, intelligence, environmental protection, low carbon, durability and long life. So is your ball mill production capacity up to standard? As a senior mineral processing equipment manufacturer, Xingaonai Heavy Industry will tell you the effective way to increase the mill production capacity.

1. What is the capacity of a ball mill in one hour?

There are many types of ball mills. Common specifications include Φ2400*5000, Φ2700*4000, Φ3200*4500, Φ3600*5000, Φ3600*6000, and Φ4000*6000. The capacities of these different types of ball mills are 10-70t/h, 22-80t/h, 35-95t/h, 46-135t/h, 53-180t/h, and 65-248t/h. In addition, the manufacturer also provides professional customization services. As long as you need it, you can contact the technical engineer online, and we will customize the equipment capacity that meets your requirements for you.

2. What factors are related to the capacity of ball mills

Undoubtedly, each type of ball mill generally has a fixed capacity limit value, but in the long-term use process, its work efficiency, production capacity, etc. will be reduced to a certain extent. In the long run, the capacity standard of the ball mill you purchased will be reduced. As for what factors are related to the capacity of ball mills? The editor of New High-resistant Heavy Industry has sorted out and introduced for you:

Steel ball grading: The ball mill uses steel balls as grinding bodies to impact and crush and grind the ore, so the grading and quality of the steel balls will be closely related to its capacity;

The greater the humidity of the ore composition and the grinding ore, the easier it is to adhere to the mill, affecting the output. At the same time, the higher the hardness of the ore and the more complex the composition, the greater the difficulty of grinding, and the lower the capacity;

Finished product particle size: The higher the finished product fineness requirement standard, the lower the production efficiency and the relatively low output.

3. There are tricks to improve the capacity of ball mills

What should I do if your ball mill capacity does not meet the standard after long-term use? In fact, it is not difficult to improve the production capacity of equipment. The manufacturers of Xingaonai Heavy Industry have their own tricks to deal with it:

Reasonable control and uniform feeding to better play the crushing and grinding capacity of the ball mill;

Regular maintenance, timely replacement of severely worn parts, keep the equipment running smoothly, and better improve work efficiency;

Improve the grinding system, upgrade the steel ball grading combination method, and improve the grinding efficiency;

Add a fine crusher in front of the mill and use it with a high-efficiency powder selector.

4. Understanding the price of ball mills

The prices of different types of ball mills are different, and the difference is tens of thousands or even hundreds of thousands. It is normal, so what is the market price of a specific ball mill? You need to consult the ball mill manufacturer online in real time to obtain it, and then go to the field for inspection and consultation, so as to ensure that you invest in a cost-effective ball mill equipment.

Xingaonai Heavy Industry is a large-scale joint-stock enterprise integrating R&D, production, sales and service. After 20 years of innovative development, it now has four major production plants and has become an enterprise with both soft and hard power in the domestic mining machinery industry. The reason why we have achieved today's success is not only because of its high-quality mechanical products and innovative technology, but also the considerate and thoughtful service is an important factor, whether it is pre-sales and after-sales service of products, or mining development general contracting project management (EPC) service. If you want to know more about the use of Xingaonai Heavy Industry ball mill, please feel free to visit us at any time.

Author: Xingaonai

Reprint address: http://xingaonai.cn/products-knowledge/methods-to-increase-ball-mill-production-capacity.html

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now