Maximum output and minimum particle size of ball mill

Xingaonai

Xingaonai

![[list:date style=M.d,Y]](/images/date.png) Mar.24,2025

Mar.24,2025

5

5

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

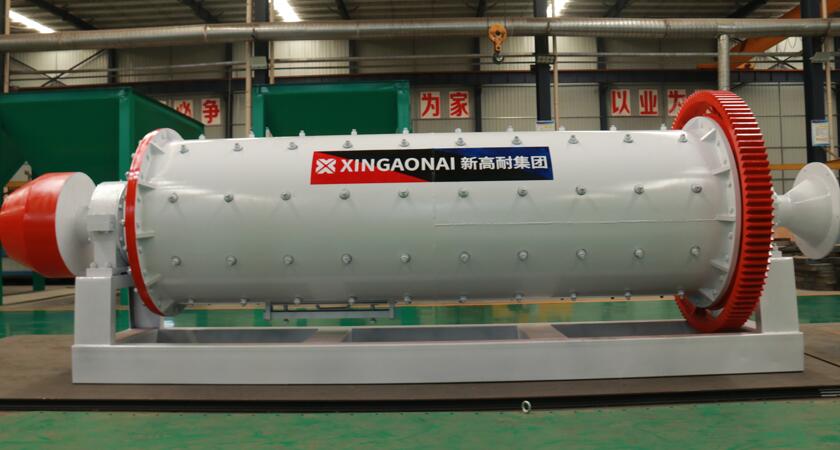

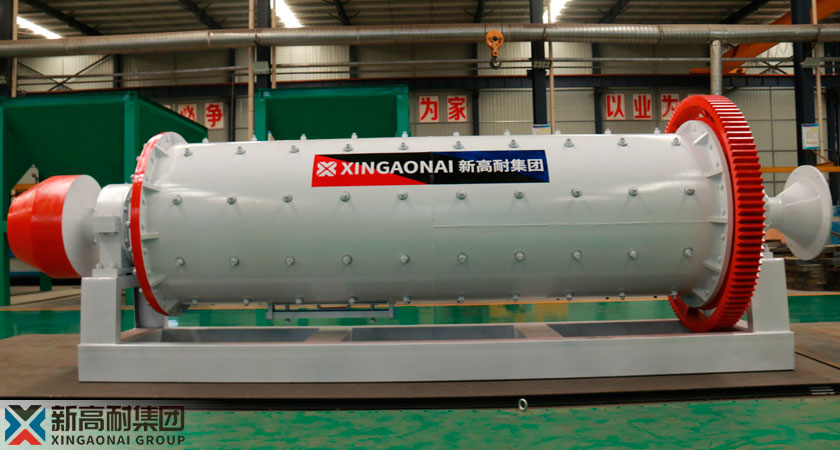

The ball mill is a common mineral processing equipment, which is mainly used to grind materials into fine powder or ultrafine powder. It is widely used in mining, cement, chemical and other industries. It grinds the materials to the required fineness by placing steel balls into the rotating mill so that they collide and rub with the materials to be ground. For such a grinding equipment, how many tons is its maximum hourly output? What particle size can be ground? Xin Gaonai will introduce it to you in detail.

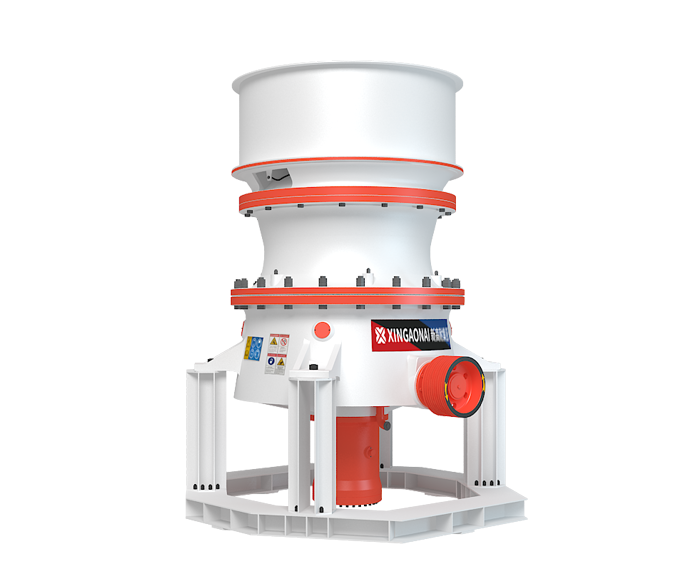

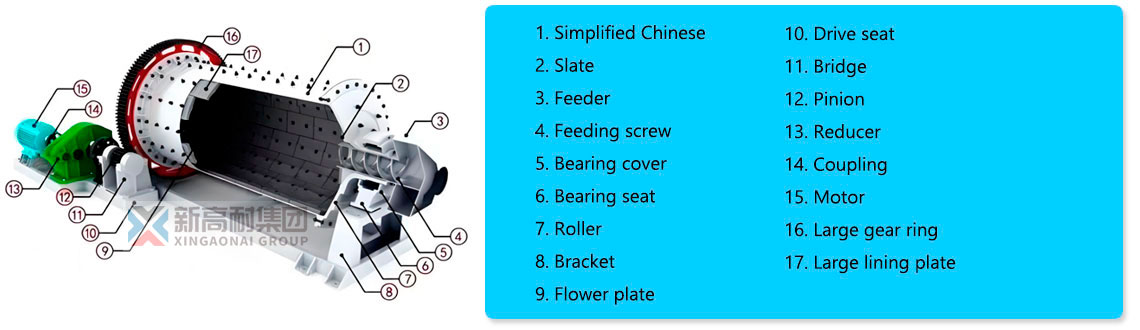

The ball mill is mainly composed of a cylinder, a transmission device, a feeding device, a discharging device, a supporting device, etc. It has a wide range of applicability, efficient grinding capacity, simple operation and maintenance, flexible parameter adjustment, economical practicality and mature technology. With the advancement of technology, the ball mill is developing in the direction of energy saving, environmental protection and intelligence, providing more efficient and reliable solutions for industrial production.

What is the maximum hourly output of the ball mill?

The maximum output of the ball mill can reach 248 tons per hour.

The output of a ball mill depends on many factors, including equipment specifications, grinding media, equipment status, operating conditions, material characteristics, feed size, and discharge particle size requirements. The ball mill equipment produced by New High-resistant Heavy Industry has an hourly output of 10-248 tons, and the specific output needs to be determined according to the actual production situation. For example, the higher the hardness of the material, the lower the grinding efficiency, and the hourly output may decrease. The selection of grinding media such as steel balls and ceramic balls will also affect the grinding efficiency. In addition, the specifications and output of ball mills are also different, ranging from 10 tons to 248 tons, covering a variety of models to meet different needs. The following lists the parameters of some ball mill models of New High-resistant Heavy Industry for customer reference.

What particle size can a ball mill grind?

The discharge particle size is basically between 0.074-0.4mm, that is, between 40-200 mesh.

How much particle size a ball mill can grind depends on many factors, including the size and material of the grinding stone or grinding ball, the filling rate, the speed of the mill, the nature of the material, etc. In order to achieve better fine grinding effect, it is recommended to take the following measures:

Choose suitable grinding stones or grinding balls: According to the properties and requirements of the materials, choose suitable grinding stones or grinding balls, including size, hardness, material, etc.

Adjust the filling rate: Reasonably adjust the filling rate to ensure full contact between the material and the grinding stone or grinding ball to achieve better fine grinding effect.

Control the speed: According to the properties and requirements of the material, appropriately adjust the speed of the mill and control the residence time of the material in the mill to achieve the best grinding effect.

Regular maintenance: Regularly check the vulnerable parts of the ball mill to ensure the normal operation of the equipment and avoid failures affecting the fine grinding effect.

When selecting a ball mill, a comprehensive evaluation should be made based on production needs, material characteristics, equipment performance and economy. It is recommended that customers must inform the ball mill manufacturer of the ore materials and grinding test results. It will be safer to ask professionals for reference. Only by choosing a ball mill of the right type and specification can efficient, stable and economical production operation be ensured.

Author: Xingaonai

Reprint address: http://xingaonai.cn/products-knowledge/maximum-output-and-minimum-particle-size-of-ball-mill.html

+86 17761642222

+86 17761642222 sales@xgnchina.com

sales@xgnchina.com

Message

Message Chat Now

Chat Now