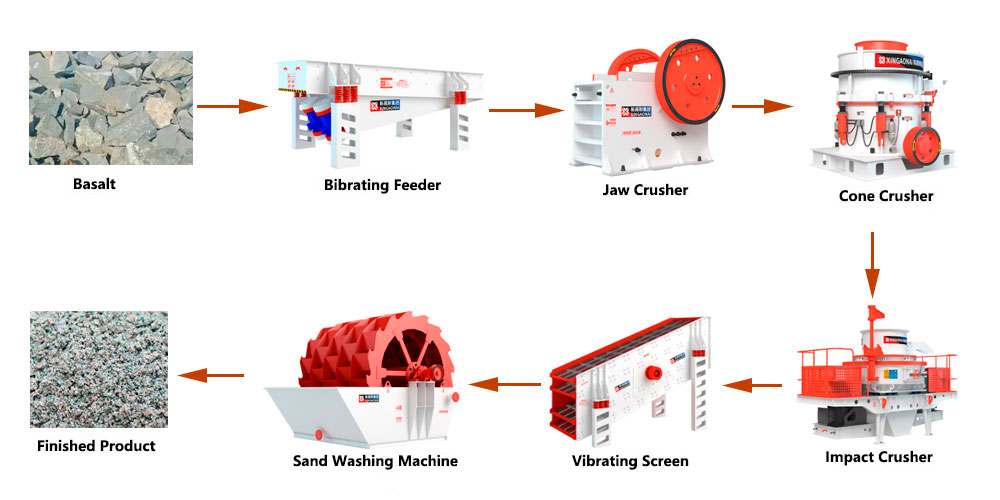

Basalt production process

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Basalt

Process introduction: The processing of basalt is divided into three stages: coarse crushing by jaw crusher, medium and fine crushing by impact crusher or cone crusher, and sand making and shaping by sand making machine.

Application areas: Basalt has a wide range of uses, and its application is not limited to the construction industry,It is the best material among the stones used to repair roads, railways, and airport runways

Process introduction

The first stage: coarse crushing

The bulk basalt materials are uniformly fed by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. After the coarsely crushed materials are screened by the vibrating screen, they are transported by the belt conveyor to the impact crusher or cone crusher. The crusher performs fine crushing.

The second stage: medium to fine crushing

The basalt transported to the impact crusher/cone crusher is medium-finely crushed and then screened using a circular vibrating screen. The larger particles are returned to the impact crusher/cone crusher for crushing again.

The third stage: sand making

The crushed basalt is sent to the sand making machine for further crushing and shaping. If clean basalt is needed, it can be sent to the sand washing machine for cleaning.

Production instance

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now