Granite uses and crusher recommendations

Xingaonai

Xingaonai

![[list:date style=M.d,Y]](/images/date.png) Mar.24,2025

Mar.24,2025

244

244

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Introduction to granite

Granite is a high-hardness, wear-resistant ore, mainly composed of quartz, feldspar and mica. It is an igneous rock formed by the slow cooling and crystallization of magma deep underground. It has a typical granular structure and the mineral particles are clearly visible. It is widely used in construction, decoration, carving and other fields.

Because the hardness of granite is relatively high between 6-7, this requires the crusher to have not only strong crushing force, but also high wear resistance and stability. Therefore, when choosing a granite crusher, its crushing ratio, processing capacity, energy efficiency and equipment durability should be focused on. Which crusher should be selected for specific granite crushing, Xin Gaonai Heavy Industry will explain in detail as follows.

Jaw crusher

Recommendation reason: suitable for primary crushing of granite, suitable for preliminary crushing of large pieces of granite.

Features: It has the characteristics of large crushing ratio, large processing capacity and strong adaptability. Its structure is simple, maintenance is convenient, and it is suitable for crushing the hardness of granite.

Scope of application: suitable for coarse crushing operations, suitable for ores and rocks with medium hardness or below.

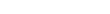

Cone Crusher

Recommendation reason: Suitable for medium-term crushing of granite, the finished product particle size is fine and uniform.

Features: Adopting the working principle of laminated crushing, it not only has high crushing efficiency and low energy consumption, but also has uniform and adjustable particle size, which is suitable for large-scale production.

Scope of application: Suitable for medium and fine crushing operations, suitable for ores and rocks with medium hardness or above.

Impact crusher

Recommendation reason: Suitable for secondary crushing of granite, where the finished product particle shape is required to be better.

Features: Using the working principle of impact crushing, not only the crushing ratio is large, but also the finished product particle shape is good and adjustable, the equipment structure is simple, and it is more suitable for the production of sand and gravel for construction.

Scope of application: Occasions with high requirements for the finished product particle shape.

Impact crusher (sand making machine)

Recommendation reason: Suitable for fine crushing and sand making of granite, where the finished product particle size is required to be extremely fine.

Features: Using the principle of high-speed rotating rotor impacting materials, not only the finished product particle shape is good, but also the equipment structure is simple and easy to operate, suitable for the production of high-quality machine-made sand.

Scope of application: Suitable for fine crushing operations, suitable for ores and rocks with hardness below high.

Hammer crusher

Recommendation reason: Suitable for medium-term crushing of granite, requiring finer particle size, suitable for small and medium-sized production, economical and affordable.

Features: Using high-speed rotating hammers to impact materials, high crushing efficiency, simple structure, and low maintenance cost.

Scope of application: Small and medium-sized quarries or occasions with limited budgets.

Selection suggestions

Primary crushing: Jaw crusher is preferred to handle large pieces of granite.

Medium and fine crushing: According to the production scale and finished product requirements, cone crusher or impact crusher is selected.

Sand making: Impact crusher is selected to produce high-quality machine-made sand.

Small and medium-scale production: Hammer crusher is an economical choice.

Production requirements: Clearly define the particle size distribution, output requirements, and whether a multi-stage crushing process is required for the required finished product, and select a suitable crusher combination based on this.

Energy consumption and environmental protection: Considering the energy efficiency of the equipment, crushers with high energy efficiency ratio, low noise, and good dust control are preferred, which meet the current requirements of environmentally friendly production.

Maintenance and cost: Long-term operating costs include equipment purchase, maintenance, energy consumption and spare parts replacement. Choose equipment that is easy to maintain, has sufficient spare parts supply and is cost-effective overall.

Manufacturer service and technical support: Complete after-sales service and technical support are the key to ensuring the stable operation of equipment. Choose manufacturers with good market reputation and the ability to provide customized solutions.

Main uses of crushed granite

Concrete aggregate: Crushed granite can be used as coarse aggregate for concrete to enhance the strength and durability of concrete.

Roadbed material: used for paving roads and railway roadbeds to provide solid support.

Building filler: used as filling material for foundations, dams and other projects.

Crushed stone paving: used for landscape paving such as gardens, courtyards, and sidewalks, which is beautiful and durable.

Waterscape design: used for waterscape design such as fountains and pools to add a natural atmosphere.

Refractory materials: Crushed granite can be used to make industrial materials such as refractory bricks.

Abrasive materials: used to make abrasive tools such as sandpaper and grinding wheels.

Filter materials: used in filtration systems such as water treatment and sewage treatment.

Agricultural use: used to improve soil structure, increase soil permeability and drainage.

Author: Xingaonai

Reprint address: http://xingaonai.cn/mineral-profile/granite-uses-and-crusher-recommendations.html

+86 15637191339

+86 15637191339 sale@xingaonai.cn

sale@xingaonai.cn

Message

Message Chat Now

Chat Now